Cryogenic plastics are indispensable in environments where temperatures can plummet to -392°F or lower. This article answers the critical question of why these materials stand out, outlining their pivotal properties, and presenting their applications within essential industries. Learn how they rise to meet the challenges of extreme cold without compromising performance or reliability.

Cryogenic plastics are high-performance materials that excel in extreme cold conditions and offer a broad operating temperature range. These plastics come with a distinctive set of advantages such as low thermal conductivity, electrical insulating properties, and a remarkable resistance to cold temperatures. Their utility is realized across an array of industries, enabling tasks like cryogenic storage, transportation, and materials handling at severely low temperatures.

Frequent candidates for cryogenic applications include high-performance thermoplastic polymers like:

These materials are known for their superior performance at very low temperatures, coupled with excellent chemical and thermal resistance, making them suitable for challenging environments with a wide operating temperature range.

The resilience of a material in cryogenic temperatures refers to its ability to sustain its properties and performance under severely cold conditions. Plastics demonstrate distinct behaviors and properties within a temperature range from −238 °F to −460 °F.

When exposed to such low temperatures, the nature of plastics undergoes a transformation. They become harder, stiffer, and more brittle, though they maintain their outstanding chemical resistance, which is vital for their applications.

What characteristics must a plastic possess to operate effectively under cryogenic conditions? Such plastics need to:

Specific types of plastics are particularly well-suited for cryogenic applications. One such material is non-brominated G10, which is a type of glass epoxy material. This material is particularly suited for cryogenic applications due to its ability to maintain excellent electrical characteristics and physical properties at cryogenic temperatures. It also exhibits a low thermal conductivity, enhancing its effectiveness as an insulator.

Plastics suitable for cryogenic applications include:

These plastics provide low thermal conductivity, electrical insulating properties, and sealing performance, all of which are advantageous in cryogenic environments. They can be fashioned into various forms, including sheets, for different applications.

It’s noteworthy that while these plastics perform admirably in cryogenic temperatures, they can become more brittle. The thermal stress from temperature fluctuations can lead to notably adverse effects. Furthermore, the volumetric changes resulting from thermal expansion and contraction can pose challenges in the processing of plastics for cryogenic systems.

Thermal expansion and contraction pertain to the changes in the size of the plastic material when subjected to temperature fluctuations. This process plays a significant role in the performance of plastics in cryogenic conditions. As these materials become more brittle due to the adverse effects of thermal stress induced by temperature, they also undergo reduced flexibility and increased brittleness. Yet, they still maintain benefits such as low thermal conductivity and electrical insulation.

The effects of thermal expansion and contraction significantly influence the selection of cryogenic plastics. These factors can impact the dimensional stability and integrity of the materials at low temperatures, which in turn affects material performance and the operating temperature range.

Moreover, the longevity of cryogenic plastic parts can be influenced by:

There are multiple methods to improve plastics’ performance at low temperatures. These include modifying their chemical structure and incorporating additives. The addition of additives, for instance, can improve the cryogenic suitability of plastics by enhancing their properties such as low thermal conductivity, electrical insulation, sealing performance, flexibility, and resistance to cracking at low temperatures. The range of additives used to enhance plastic performance at cryogenic temperatures includes acrylonitrile, butadiene, styrene, and rubbers. While these additives enhance performance, fillers can make plastics more brittle at low temperatures, thereby influencing their impact strength and scratch resistance.

Processing techniques also significantly contribute to increasing the durability of plastics in cryogenic conditions. Methods like deep cryogenic treatment and cryogenic treating can minimize issues during the molding process, decrease the chances of warping, and yield a more resilient product with an extended lifespan. These techniques also enhance strength, durability, and wear resistance.

A plastic’s cryogenic performance is largely influenced by its chemical structure. The molecular structure of plastics can lead to increased hardness, stiffness, and brittleness, effects that are particularly significant at cryogenic temperatures.

Thermoset and thermoplastic polymers, along with fluorinated polymers such as:

Examples of successful modifications in the chemical structure of plastics for cryogenic use include the development of thermoset and thermoplastic polymers specifically designed for such conditions, as well as the utilization of high-performance thermoplastics such as Ultem®, Radel® R, PEEK, and DuPont™ Vespel®.

To further enhance the cryogenic properties of plastics, a range of toughening agents can be introduced. These include:

The performance of plastics under cryogenic conditions is greatly affected by additives and fillers. Typical additives employed in cryogenic plastics include:

Fillers that contribute to cost reduction during manufacturing

Plasticizers that decrease the glass transition temperature of the polymer

Additives like talc, calcium carbonate, and oil composition that can prolong the material’s lifespan, diminish flammability, enhance flexibility, and streamline processing, thereby bolstering cryogenic suitability.

Fillers, on the other hand, enhance the durability and resistance of plastics at low temperatures by improving:

Fibers such as glass and carbon fibers, in particular, enhance impact resistance due to their large aspect ratio.

The variety of fillers used in cryogenic plastics include:

These fillers are added into polymers to improve tensile strength, modulus, friction, and wear performance. These enhancements are critical for preserving material properties at cryogenic temperatures.

The durability of plastics under cryogenic conditions can be substantially improved through processing techniques like annealing and stress-relieving. Annealing, for instance, can enhance the durability of plastics at cryogenic temperatures through the development of microstructures and mechanical properties, leading to an increase in impact strength up to a specific annealing temperature, beyond which it stabilizes.

Stress-relieving, on the other hand, reduces residual stress, which in turn improves material durability and performance.

Molding processes, such as injection molding and cryogenic deflashing, also impact the durability of cryogenic plastics. They produce accurate molded parts and eliminate surplus material, which can impact properties like thermal conductivity, electrical insulation, and sealing performance.

With their distinctive properties, cryogenic plastics are employed in a variety of industries including:

In aerospace and space exploration, cryogenic plastics play a crucial role by reinforcing metal parts in systems like communications, guidance, and landing gear. They are also essential in the production of industrial pumps and valves, and are necessary for cryogenic cooling in specific applications.

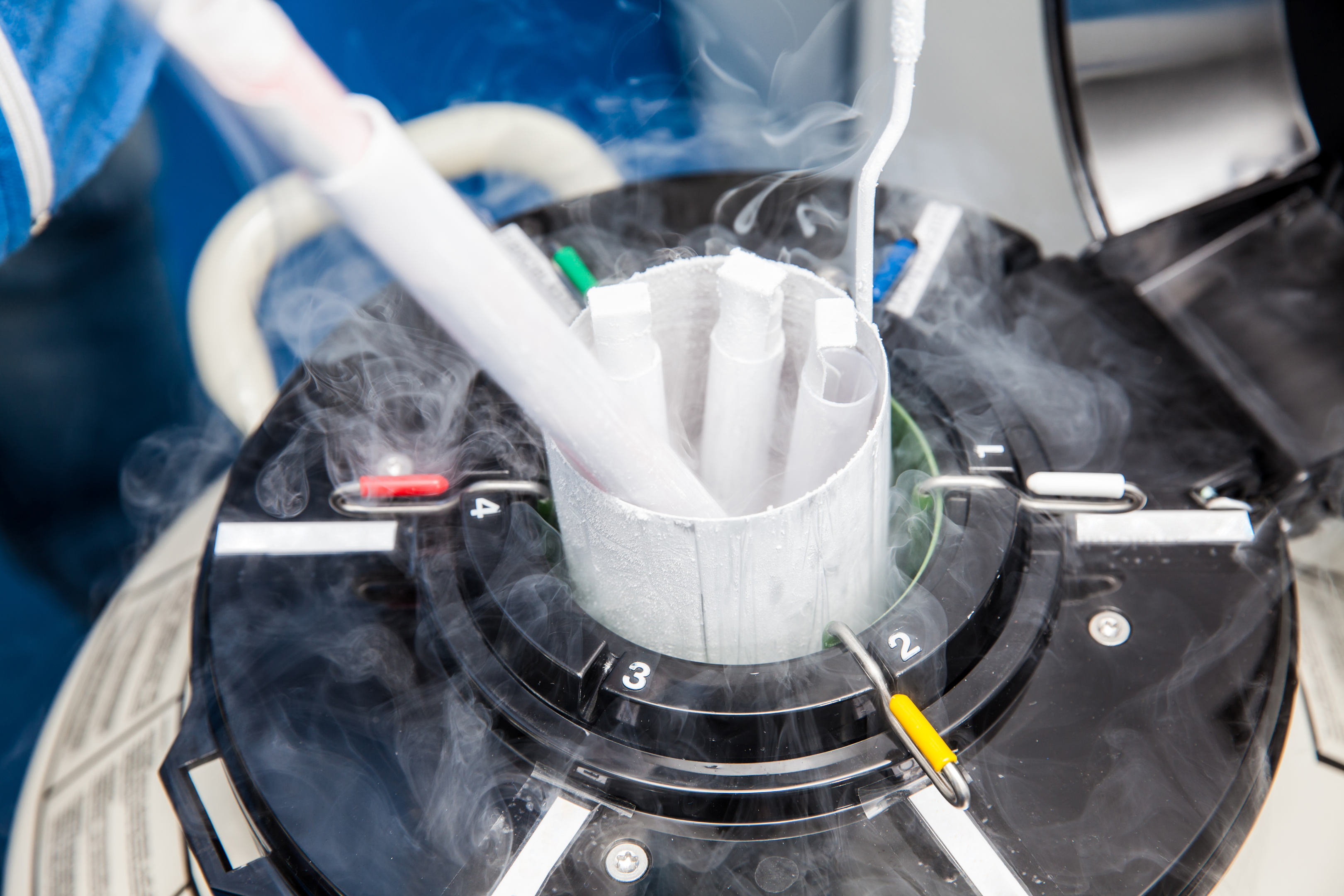

In the medical sector, cryogenic plastics are instrumental in a range of equipment, from cryogenic storage boxes and processors to pressure vessels and cryo tanks. Similarly, in the oil and gas industry, they are used in standoffs and gaskets, where polymer seals offer a dependable and long-lasting seal capable of enduring exceptionally low temperatures, effectively averting fluid and gas leakage.

In the aerospace industry and space exploration, cryogenic plastics play a prominent role. The plastics utilized in these components must possess the following characteristics:

Cryogenic plastics are favored for aerospace and space exploration components due to the following reasons:

These qualities make cryogenic plastics highly suitable for these applications.

Thermoplastics, thermoplastic composites, and plastic materials, including high performance thermoplastic polymer, are frequently utilized in the aerospace industry and space exploration.

Extreme temperatures in space can cause cryogenic plastic components to become more brittle and exacerbate the adverse effects of thermal stress caused by temperature fluctuations.

Medical and scientific equipment also extensively utilize cryogenic plastics. Equipment such as cryogenic storage boxes, processors, pressure vessels, cryo tanks, racks, refrigerators, temperature controllers, and cryogenic tanks incorporate these plastics. The advantages of cryogenic plastics in such apparatus encompass heightened strength and durability, enhanced wear resistance, improved performance, cost reduction, lightweight characteristics, high specific strength, outstanding corrosion resistance, favorable anti-fatigue performance, and the possibility of tailored designs.

Cryogenic plastics are utilized in MRI machines to cool the magnets to near absolute zero, resulting in a significant reduction in power consumption due to the elimination of continuous cooling requirements. In the selection of cryogenic plastics for such purposes, it is important to consider factors such as the material’s low thermal conductivity, electrical insulating properties, sealing performance, and the design of the seal to ensure optimal operation of the equipment at cryogenic temperatures.

Cryogenic plastics are critically important in the production of standoffs and gaskets in the oil and gas industry. Plastic standoffs employed in this industry need to exhibit durability, longevity, and resistance to severe environmental conditions. PEEK plastic is an example of a material that possesses these attributes for standoffs.

Standoffs and gaskets made from cryogenic plastics are engineered to endure low temperatures and challenging conditions through the provision of a vacuum-tight seal and the use of materials that are resistant to becoming hard and brittle at low temperatures.

In comparison to other materials, cryogenic plastics provide a multitude of advantages for utilization in standoffs and gaskets within the oil and gas industry. These advantages include:

These advantages are crucial for the resilience and longevity of these components in a demanding sector.

Additionally, cryogenic plastics play a vital role in managing and storing cryogenic liquids. They possess specific characteristics, including low thermal conductivity, electrical insulating properties, and sealing performance, making them suitable for handling and storage of cryogenic liquids.

Cryogenic plastics are able to withstand extreme temperatures of cryogenic liquids thanks to their distinctive blend of:

The plastics commonly employed in the storage and handling of cryogenic liquids include:

Established industry standards for plastics utilized in the storage and handling of cryogenic liquids encompass several key practices. These include:

Compared to other materials like metals and ceramics, cryogenic plastics offer distinct advantages. For instance, cryogenic plastics typically exhibit increased strength, stiffness, hardness, and brittleness in cold temperatures, whereas only a limited number of metals are suitable for use under these conditions. The thermal properties of metals and ceramics at cryogenic temperatures have been extensively documented, encompassing characteristics such as thermal conductivity, specific heat, and thermal expansion.

Cryogenic plastics, within the realm of plastics, exhibit unique thermal behaviors that can offer advantages in specific applications. Some key advantages of cryogenic plastics include:

These advantages make cryogenic plastics more appealing for a diverse array of applications.

Industry-specific needs and requirements can be met through custom solutions using cryogenic plastics. The predominant methods and technologies utilized in the development of customized solutions with cryogenic plastics include rotational molding, injection molding, and 3D printing with ABS.

Tailoring cryogenic plastic properties for specific applications can be achieved by choosing high-performance thermoplastics that exhibit excellent performance in cryogenic temperatures. Plastics can serve as seals, structural components, and bearing and wear components in cryogenic applications.

The customization of cryogenic plastic solutions can impact the cost by enabling tailored designs and materials to meet specific requirements, potentially leading to an overall cost increase. Furthermore, customization may involve additional processes or equipment, which can also affect the cost.

Examples of customized applications involving cryogenic plastics include:

Several factors contribute to the longevity of cryogenic plastic parts, including:

It is typically recommended to inspect and potentially replace these components every 6 years to maintain their continued performance.

Temperature fluctuations can cause thermal degradation of cryogenic plastics, leading to a decrease in strength and toughness, and an increase in brittleness. These changes can have an impact on the material’s longevity and reliability.

Indications of deterioration in cryogenic plastic parts encompass an escalation in brittleness, decrease in ductility, and susceptibility to shattering, signifying the necessity for maintenance or potential replacement to avert failure.

In conclusion, the versatility and resilience of cryogenic plastics make them an invaluable resource in various industries, be it aerospace, medical, oil and gas, or the handling and storage of cryogenic liquids. Their unique properties, coupled with the possibilities of customization and the potential for longevity, place them in a league of their own, providing a compelling solution for even the most demanding applications.

PTFE, or PolyTetraFluoroEthylene, is commonly used for cryogenics due to its outstanding chemical resistance, wide temperature range from cryogenic to 500F, and other beneficial properties.

The best cryogenic plastics include PolyTetraFluoroEthylene (PTFE) and Non-Brominated G10, which haveoutstanding chemical resistance,, wide operating temperature range, high impact strength, and self-lubricating properties. This makes it suitable for cryogenic applications and beyond.

Examples of cryogenic materials include nitrogen, helium, hydrogen, argon, methane, and carbon monoxide. These substances have boiling points below minus 130 degrees F (minus 90 degrees C) and are used for frozen storage and experimentation.

Thermal expansion and contraction cause changes in the size of cryogenic plastics due to temperature variations. These changes are important to consider in the design and application of cryogenic plastic materials.

To enhance the performance of plastics at low temperatures, you can modify their chemical structure and add certain additives for improved results.